3.8. LinuxCNC Configuration¶

As noted in Section 3.6.2, a LinuxCNC configuration comprises several files, requiring at least one INI file and one HAL file. The following sections detail the configuration of both file types, using the mesa_7i96s_7i77_xy configuration as an example.

3.8.1. INI Configuration¶

3.8.1.1. .ini Configuration File Format¶

An .ini file is a plain text file used for configuring applications and programs. It has a simple structure consisting of sections and key-value pairs. The basic syntax of an .ini file is as follows:

Sections: Sections serve to organize keys and values. Each section begins with its name enclosed in square brackets, followed by zero or more key-value pairs belonging to that section. The syntax for a section is:

[section_name]Keys and Values: Within each section, keys and their corresponding values can be defined. Keys are identifiers used to access associated values. The syntax for a key-value pair is:

key = value

Keys can contain letters and underscores (

_). Values can be text strings, integers, or floating-point numbers.Comments: Comments begin with a semicolon (

;) or a hash symbol (#). For example:; This is a comment # This is also a comment

3.8.1.2. Example: mesa_7i96s_7i77_xy.ini Configuration File¶

Below are the different sections of the mesa_7i96s_7i77_xy.ini configuration file, with comments explaining the purpose of each parameter. Note that not all available parameters are specified in some sections. For a complete list of parameters and their documentation, consult the LinuxCNC user manual [lin23].

EMC Section: General configuration.

1[EMC] 2# General configuration 3 4# Machine name, usually displayed in the interface window. 5MACHINE = mesa_7i96s 6 7# Debug flags, 0 will not print debug messages. 8DEBUG = 0 9 10# Configuration version, for LinuxCNC 2.9 it should be 1.1. 11VERSION = 1.1

DISPLAY Section: User interface configuration. The available options may depend on the specific user interface used. In this case, we are using the AXIS user interface.

14[DISPLAY] 15# Graphic interface configuration 16 17# Type of graphic interface to use. 18DISPLAY = axis 19 20# Coordinate system: RELATIVE or MACHINE. 21POSITION_OFFSET = MACHINE 22 23# Coordinates to display: COMMANDED or ACTUAL. 24POSITION_FEEDBACK = ACTUAL 25 26# Maximum "feed override". A "feed override" of 2 means 27# 200% of the programmed "feed rate". 28MAX_FEED_OVERRIDE = 2.000000 29 30# Image to display on the splash screen. 31INTRO_GRAPHIC = linuxcnc.gif 32 33# Maximum time in seconds for the splash screen. 34INTRO_TIME = 5 35 36# Default directory for G-code programs. 37PROGRAM_PREFIX = /home/gtec/linuxcnc/nc_files 38 39# Increments to move the robot with manual control. 40INCREMENTS = 5mm 1mm .5mm .1mm .05mm .01mm .005mm 41 42# The coordinate value to be displayed: COMMANDED or ACTUAL 43POSITION_FEEDBACK = ACTUAL 44 45# Default linear velocity with manual control. 46DEFAULT_LINEAR_VELOCITY = 1.000000 47 48# Maximum allowed linear velocity with manual control. 49MAX_LINEAR_VELOCITY = 10.000000 50 51# Minimum allowed linear velocity with manual control. 52MIN_LINEAR_VELOCITY = 0.000000 53 54# Text editor to use when clicking File -> Edit. 55EDITOR = mousepad 56 57# Geometry of the 3D view in the preview window. 58GEOMETRY = XY 59 60# Refresh time in milliseconds. 61CYCLE_TIME = 100 62 63# File to open when starting LinuxCNC (optional). 64OPEN_FILE = ""

TASK Section: LinuxCNC task controller configuration. The task controller is responsible for communicating with the user interface, the motion planner, and the G-code interpreter. Currently,

milltaskis the only task controller available. For more information, consult the LinuxCNC user manual [lin23] and themilltaskman page, also available at http://linuxcnc.org/docs/devel/html/man/man1/milltask.1.html.67[TASK] 68# Task controller configuration 69 70# Task controller module, milltask. 71TASK = milltask 72 73# Execution period of milltask. 74CYCLE_TIME = 0.010

RS274NGC Section: RS274NGC (G-code) interpreter configuration.

77[RS274NGC] 78# RS274NGC interpreter configuration 79 80# Interpreter variable file. 81PARAMETER_FILE = linuxcnc.var 82 83# Startup codes for the interpreter. 84RS274NGC_STARTUP_CODE = G21 G40 G90 G94 G97 G64 P0.025

EMCMOT Section: Motion controller configuration. The

EMCMOTandSERVO_PERIODparameters are not directly used by LinuxCNC but are used to configure the motion control module in the HAL file (see Section 3.8.2).87[EMCMOT] 88# Motion controller configuration 89 90# Motion controller module, motmod. 91# Not used by LinuxCNC directly, used in the HAL file. 92EMCMOT = motmod 93 94# Number of seconds to wait for the motion module to 95# confirm receipt of messages from the task module. 96COMM_TIMEOUT = 1.0 97 98# "servo" thread period 99# Not used by LinuxCNC directly, used in the HAL file. 100SERVO_PERIOD = 1000000

HAL Section: HAL configuration.

103[HAL] 104# Hardware Abstraction Layer (HAL) configuration 105 106# Add the HAL user interface pins. 107HALUI = halui 108 109# HAL file to execute when starting LinuxCNC. 110# Can be specified multiple times. 111HALFILE = mesa_7i96s_7i77_xy.hal 112 113# HAL file to execute after loading the graphical interface. 114POSTGUI_HALFILE = postgui.hal 115 116# HAL file to execute when closing LinuxCNC. 117SHUTDOWN = shutdown.hal

HALUI Section: HALUI (HAL-based user interface) configuration. The only available option is

MDI_COMMAND, which allows MDI commands to be executed via HAL signals. In our case, this section is left empty.120[HALUI] 121# HAL User Interface 122 123# MDI Command. Can be specified multiple times. 124# To execute it use the halui.mdi-command-NN pin, 125# where NN is the command number. 126# MDI_COMMAND = G1 X0 Y0 Z0

KINS Section: Kinematics configuration.

129[KINS] 130# Kinematics 131 132# Number of joints (motors). 133JOINTS = 2 134 135# Kinematics module 136# Not used by LinuxCNC directly, used in the HAL file. 137KINEMATICS = trivkins coordinates=XY

APPLICATIONS Section: LinuxCNC allows applications to be launched at startup. These applications must be specified within the

APPLICATIONSsection using theAPPoption, which can be used multiple times. Applications will be launched either at the beginning, before the graphical interface starts, or after a delay specified by theDELAYoption.140[APPLICATIONS] 141# Additional applications 142 143# Application to execute. Can be specified multiple times. 144APP=halscope 50000

TRAJ Section: Trajectory planner configuration.

147[TRAJ] 148# Trajectory planner configuration 149 150# Controlled axes. Possible values: X, Y, Z, A, B, C, U, V, W. 151# An axis can be specified more than once, e.g., XXYZ. 152COORDINATES = XY 153 154# Units for linear axes. 155LINEAR_UNITS = mm 156 157# Units for rotary axes. 158ANGULAR_UNITS = degree 159 160# Maximum linear velocity, in units per second. 161MAX_LINEAR_VELOCITY = 12.00 162 163# Maximum linear acceleration, in units per second^2. 164MAX_LINEAR_ACCELERATION = 20.0

EMCIO Section: Input/output controller configuration. This controls input/output tasks such as coolant, tool changes, and emergency stops.

167[EMCIO] 168# Input/Output (I/O) controller configuration 169 170# Input/output controller module. 171EMCIO = io 172 173# Period at which EMCIO will be executed. 174CYCLE_TIME = 0.100

AXIS_<i> Section: Configuration for axis <i>. Possible values for <i> include

X,Y,Z,A,B,C,U,V, andW. An example of the X-axis configuration is provided below; the Y-axis configuration is similar.Important

When configuring the robot’s limits (

MIN_LIMITandMAX_LIMITparameters), it is advisable to leave some margin beyond the desired workspace. If the robot is commanded to position itself at one of the limits, it can easily exceed that limit slightly. For example, if you want your robot to operate on the X-axis between X = 0 and X = 200, you could configureMIN_LIMIT = -5andMAX_LIMIT = 205.177[AXIS_X] 178# X axis configuration 179 180# Maximum axis velocity, in units per second. 181MAX_VELOCITY = 12.0 182 183# Maximum axis acceleration, in units per second^2. 184MAX_ACCELERATION = 20.0 185 186# Minimum limit for the axis, in machine units. 187MIN_LIMIT = -5 188 189# Maximum limit for the axis, in machine units. 190MAX_LIMIT = 205.0

JOINT_<n> Section: Configuration for joint (motor) <n>, where <n> is the joint number, ranging from 0 to (<num_joints> \(-\) 1). The value of <num_joints> is set in the

JOINTSoption of theKINSsection.For machines with Cartesian geometries, such as gantry robots, LinuxCNC includes the

trivkinskinematics module. With this module, by default, there is a 1:1 correspondence between the axis coordinate letter and the joint number, i.e., JOINT_0 = X, JOINT_1 = Y, …, JOINT_8 = W.The

trivkinsmodule accepts thecoordinatesparameter to specify the association of axis coordinate letters with the joint number. For example, with the parametercoordinates=XZ, JOINT_0 will be assigned to X and JOINT_1 to Z. In this parameter, the same axis letter can be specified multiple times, allowing multiple joints to be assigned to the same axis. In this case, it is also necessary to use thekinstype=Bparameter. For instance, with the parameterscoordinates=XXandkinstype=B, both JOINT_0 and JOINT_1 will be assigned to X.For more information about the

trivkinskinematics module, consult thekinsman page, also available at http://linuxcnc.org/docs/devel/html/man/man9/kins.9.html.Important

Both the joint and axis configurations include

MAX_VELOCITY,MAX_ACCELERATION,MIN_LIMIT, andMAX_LIMITparameters. When the robot is not homed, LinuxCNC uses the parameters from the joint sections; however, once the robot is homed, it uses the parameters from the axis sections.The following code shows the configuration of joint 1 (X-axis), which corresponds to the stepper motor. The parameters specified below the comment “Custom configurations for the HAL file” are not directly used by LinuxCNC; they are used to configure the motor parameters in the HAL file (see Section 3.8.2).

193[JOINT_0] 194# Configuration of the first linear motor (X axis) 195 196# Motor type, LINEAR or ANGULAR. 197TYPE = LINEAR 198 199# Maximum tracking error, in machine units. 200FERROR = 1.0 201 202# Maximum tracking error at slow speeds. 203MIN_FERROR = 0.2 204 205# Maximum motor velocity, in units per second. 206MAX_VELOCITY = 12.0 207 208# Maximum motor acceleration, in units per second^2. 209MAX_ACCELERATION = 20.0 210 211# Minimum motor limit, in machine units. 212MIN_LIMIT = -5 213 214# Maximum motor limit, in machine units. 215MAX_LIMIT = 205.0 216 217# Position to which the joint will move upon completion of 218# the homing process. 219HOME = 0 220 221# Used to define the homing order. 222HOME_SEQUENCE = 0 223 224# Home switch position, in machine units. 225HOME_OFFSET = -10 226 227# Initial homing search velocity, in units per second. 228HOME_SEARCH_VEL = -1 229 230# Final homing search velocity, in units per second. 231HOME_LATCH_VEL = -0.25 232 233# Final homing velocity, in units per second. 234HOME_FINAL_VEL = 2 235 236# Ignore limit switches during homing. 237# = YES if the same switch is used for limits and homing. 238HOME_IGNORE_LIMITS = YES 239 240# The switch is shared with another joint. 241HOME_IS_SHARED = 0 242 243# Use the encoder's index pulse for homing. 244HOME_USE_INDEX = NO 245 246# --------------------------------------------------- 247# Custom configurations for the HAL file. 248# --------------------------------------------------- 249 250# *** Step generation configuration *** 251 252# Minimum duration of the stable direction signal before 253# starting a step, in nanoseconds. 254DIRSETUP = 10000 255 256# Minimum duration of the direction signal after finishing 257# a step, in nanoseconds. 258DIRHOLD = 10000 259 260# Duration of the step signal, in nanoseconds. 261STEPLEN = 2500 262 263# Minimum interval between step signals, in nanoseconds. 264STEPSPACE = 2500 265 266# Step scale. position = steps / STEP_SCALE. 267# To move the axis 1mm/rev with a 1.8° step motor and 1/32 268# step mode, STEP_SCALE = steps / position = (32*360/1.8)/1 = 6400 269STEP_SCALE = 6400 270 271# Maximum velocity, in position units per second. 272STEPGEN_MAXVEL = 17 273 274# Maximum acceleration, in position units per second^2. 275STEPGEN_MAXACCEL = 62.5 276 277# Note: It is recommended that STEPGEN_MAXVEL and STEPGEN_MAXACCEL be 278# between 1% and 25% larger than MAX_VELOCITY and MAX_ACCELERATION. 279 280 281# *** Encoder configuration *** 282 283# Encoder scale. position = counts / ENCODER_SCALE. 284# To get 1mm/rev with a 1000 ppr encoder (4000 cpr), 285# ENCODER_SCALE = counts / position = 4000 / 1 = 4000 286ENCODER_SCALE = 4000.0 287 288 289# *** PID controller configuration *** 290 291P = 50.0 292I = 20.0 293D = 0.0 294FF0 = 0.0 295FF1 = 1.0 296FF2 = 0.025 297BIAS = 0.0 298DEADBAND = 0.0 299MAX_OUTPUT = 0.0

The following code shows the configuration of joint 2 (Y-axis), which corresponds to the brushless motor. As before, the parameters specified below the comment “Custom configurations for the HAL file” are not directly used by LinuxCNC; they are used to configure the motor parameters in the HAL file (see Section 3.8.2). These parameters differ from the previous ones because now a brushless motor is used.

318[JOINT_1] 319# Configuration of the second linear motor (Y axis) 320 321# Motor type, LINEAR or ANGULAR. 322TYPE = LINEAR 323 324# Maximum tracking error, in machine units. 325FERROR = 1 326 327# Maximum tracking error at slow speeds. 328MIN_FERROR = 0.2 329 330# Maximum motor velocity, in units per second. 331MAX_VELOCITY = 12.0 332 333# Maximum motor acceleration, in units per second^2. 334MAX_ACCELERATION = 20.0 335 336# Minimum motor limit, in machine units. 337MIN_LIMIT = -5 338 339# Maximum motor limit, in machine units. 340MAX_LIMIT = 205.0 341 342# Position to which the joint will move upon completion of 343# the homing process. 344HOME = 0 345 346# Used to define the homing order. 347HOME_SEQUENCE = 1 348 349# Home switch position, in machine units. 350HOME_OFFSET = -10 351 352# Initial homing search velocity, in units per second. 353HOME_SEARCH_VEL = -1 354 355# Final homing search velocity, in units per second. 356HOME_LATCH_VEL = -0.25 357 358# Final homing velocity, in units per second. 359HOME_FINAL_VEL = 2 360 361# Ignore limit switches during homing. 362# = YES if the same switch is used for limits and homing. 363HOME_IGNORE_LIMITS = YES 364 365# The switch is shared with another joint. 366HOME_IS_SHARED = 0 367 368# Use the encoder's index pulse for homing. 369HOME_USE_INDEX = NO 370 371# --------------------------------------------------- 372# Custom configurations for the HAL file. 373# --------------------------------------------------- 374 375# *** Analog output configuration for +-10V *** 376 377# Maximum velocity in units per second. 378ANALOGOUT_MAXLIM = 50 379 380# Minimum velocity in units per second. 381ANALOGOUT_MINLIM = -50 382 383# Analog output scale. Vout = 10 * velocity / ANALOGOUT_SCALE. 384# Maximum velocity in units per second that the motor can reach. 385# For a max velocity of X rpm, with Y ppr encoder (4*Y cpr), 386# ANALOGOUT_SCALE = X / 60 * ENCODER_SCALE / (4*Y). 387# For 3000 rpm, ANALOGOUT_SCALE = 3000 / 60 * 2048 / 2048 = 50 388ANALOGOUT_SCALE = 50 389 390 391# *** Encoder configuration *** 392 393# Encoder scale. position = counts / ENCODER_SCALE. 394# To get 1mm/rev with a 512 ppr encoder (2048 cpr), 395# ENCODER_SCALE = counts / position = 2048 / 1 = 2048 396ENCODER_SCALE = 2048.0 397 398 399# *** PID controller configuration *** 400 401P = 20.0 402I = 10.0 403D = 0.0 404FF0 = 0.0 405FF1 = 1.0 406FF2 = 0.01 407BIAS = 0.0 408DEADBAND = 0.0 409MAX_OUTPUT = 0.0

3.8.2. HAL Configuration¶

HAL is a fundamental component of LinuxCNC, serving as an interface between the machine’s software and hardware. It provides the infrastructure for communication among the system’s numerous software and hardware components. The HAL layer is composed of components that:

Are interconnected, processing incoming data and providing outputs to other components (e.g., the motion planning algorithm instructs the motors on their movement).

Possess the ability to communicate with hardware.

Always run periodically in one of the following ways:

As real-time components, either with an execution frequency of a few microseconds (e.g., to advance a stepper motor or read an encoder) or with a frequency less than one millisecond (e.g., to adjust the planning of subsequent movements to complete a G-code instruction).

As non-real-time user-space components, which can be interrupted or delayed if the rest of the system is busy or overloaded.

The HAL components included with LinuxCNC are listed in the user manual [lin23], also available at http://linuxcnc.org/docs/stable/html/hal/components.html. Additionally, each component has its own man page.

3.8.2.1. Basic Concepts¶

Pins and Signals: HAL is based on the same principles used to design electrical circuits and hardware systems, employing “pins” and “signals” to represent the flow of data between HAL modules or components. In summary:

Pins can carry boolean, float, and signed or unsigned integer values.

Pins have a direction: input (IN), output (OUT), or input/output (I/O).

A signal identifies a connection between pins.

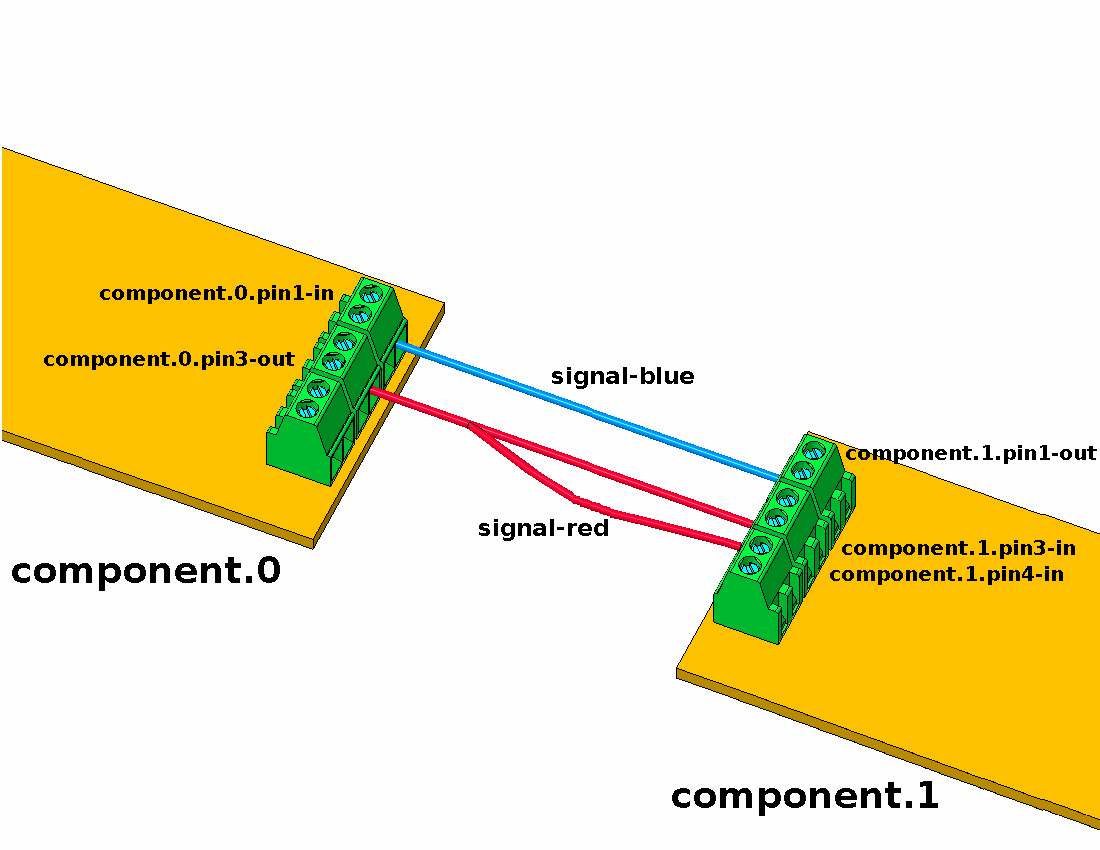

Fig. 26 from the LinuxCNC documentation [lin23] illustrates the concepts of components, pins, and signals in HAL. In the figure, pin

pin3-outofcomponent.0connects to pinspin3-inandpin4-inofcomponent.1(via thesignal-redsignal), and pinpin1-outofcomponent.1connects to pinpin1-inofcomponent.0(via thesignal bluesignal).

Fig. 26 HAL Concept — Connection as electrical circuits. Source: LinuxCNC documentation [lin23].¶

Parameters: HAL components can have parameters, which are input or output settings not connected to any other component. There are two types of parameters:

Input parameters: Values that the user can adjust and that remain fixed once configured.

Output parameters: Values that cannot be adjusted by the user. They allow for internal signals to be monitored.

Functions: Each HAL component has one or more functions that must be executed to perform the component’s task. For these functions to be executed, they must be added to a thread.

Threads: Threads enable HAL component functions to be executed at specific time intervals. When a thread is created, the time interval at which its assigned functions will be executed is specified. Subsequently, the functions of the HAL components can be added to the thread to be executed in order at the thread’s defined time interval.

3.8.2.2. Interaction with HAL and Commands¶

HAL does not interact directly with the user. LinuxCNC provides various interfaces to configure or interact with HAL:

From

.halfiles.From the command line using the

halcmdcommand.From Python scripts.

From C/C++ programs.

Configuration or interaction with HAL using any of these interfaces is performed through commands. The complete list of commands is detailed in the halcmd man page, also available at http://linuxcnc.org/docs/html/man/man1/halcmd.1.html. The most relevant commands are:

Note

Generally, each command must be specified on a single line. If a command needs to be split across multiple lines, a backslash (\) character can be used to indicate that the line continues to the next. The backslash must be the last character before the new line.

loadrt: Loads a HAL real-time component into the system. The basic syntax of theloadrtcommand is:loadrt <component> <options>

where

<component>is the name of the component and<options>are the component options. For example:loadrt mux4 count=1

addf: Adds a function to a real-time thread. The syntax of theaddfcommand is:addf <function> <thread>

where

<function>is the name of the function and<thread>is the thread to which it will be added. For example:addf mux4.0 servo-thread

loadusr: Loads a non-real-time HAL component into the system. Non-real-time components are separate processes that can optionally communicate with other HAL components via pins and parameters. Real-time components cannot be loaded into non-real-time space. The syntax of theloadusrcommand is:loadusr [<flags>] <command>

where

<command>is the program command to be executed and<flags>can be one or more of the following options:-i: Ignore the program’s return value (with-w).-w: Wait for the program to finish.-W: Wait for the component to be ready. It is assumed that the component will have the same name as the first argument of the command.-Wn``<name>: Wait for the component to be ready and assign it the name<name>. This is only applicable if the component has the-noption to assign a name.For example:

loadusr -Wn spindle gs2_vfd -n spindle

net: Creates a connection between a signal and one or more pins. The syntax is as follows:net <signal> <pin>

where

<signal>is the name of the signal and<pin>is the name of a pin. If the signal does not exist, a new signal is created. The command also allows the use of the words<=,=>, and<=>, separated by a space from the pin names, to indicate the direction of the signals between pins. These words are ignored by the command and merely serve to facilitate readability.The following rules must be met to connect a pin to a signal:

An input (IN) pin can always be connected to a signal.

An input/output (I/O) pin can be connected unless there is an output (OUT) pin on the signal.

An output (OUT) pin can be connected only if there are no other output (OUT) or input/output (I/O) pins on the signal.

The same signal name can be used in multiple

netcommands to connect additional pins, provided the above rules are respected.Examples:

net home-x joint.0.home-sw-in <= parport.0.pin-11-in

where

home-xis the signal name,joint.0.home-sw-inis an input (IN) pin,<=is the optional direction arrow (ignored by the command), andparport.0.pin-11-inis an output (OUT) pin.This example can also be equivalently defined in HAL by two

netcommands:net home-x <= parport.0.pin-11-in net home-x => joint-0.home-sw-in

Note

As seen in this example, although the second pin’s name has the

-insuffix, HAL treats it as an output pin. Therefore, when configuring pin connections in HAL, always refer to how the pin is configured in HAL, not just its name.net xStep stepgen.0.out => parport.0.pin-02-out parport.0.pin-08-out

where

xStepis the signal name,stepgen.0.outis an output pin, andparport.0.pin-02-outandparport.0.pin-08-outare input pins.This example can also be defined in HAL by two

netcommands as follows:net home-x <= stepgen.0.out net home-x => parport.0.pin-02-out parport.0.pin-08-out

setp: Sets the value of a pin or parameter. Valid values depend on the pin or parameter’s data type. The syntax of this command is:setp <name> <value>

where

<name>is the name of the pin or parameter and<value>is the value to which it is to be set. The command will fail if<name>does not exist as a pin or parameter, if it is a read-only parameter, if it is an output (OUT) pin, if it is a pin that is already connected to a signal, or if<value>is not a valid value for the pin or parameter’s data type.sets: Sets the value of a signal. The syntax is:sets <signal> <value>

where

<signal>is the name of the signal and<value>is the value to which it is to be set. The command will fail if<signal>does not exist as a signal, if the signal is already connected to an output (OUT) pin, or if<value>is not a valid value for the signal’s data type.unlinkp: Unlinks a pin from its connected signal. The syntax of the command is:unlinkp <name>

where

<name>is the name of the pin. If the pin does not have a connected signal, nothing happens. The command will fail if<name>does not exist as a pin.

3.8.2.3. .hal File Format¶

A .hal file is a plain text file containing HAL commands. Comments can be included by starting lines with the hash symbol (#). Options from the .ini file can be accessed with the syntax [<section>]<option>, where [<section>] is the section name in square brackets and <option> is the corresponding option name within that section.

3.8.2.4. Example: mesa_7i96s_7i77_xy.hal Configuration File¶

As noted in Section 3.6.2, a LinuxCNC configuration includes at least one .ini file and one .hal file. Below is the mesa_7i96s_7i77_xy.hal configuration file, corresponding to the mesa_7i96s_7i77_xy.ini file detailed in Section 3.8.1. Unlike the .ini format, the .hal format does not have a formal section syntax; however, for clarity, the file is presented below divided into different parts.

Load modules, add functions to threads, and other initial configurations:

1# Load kinematics module 2loadrt [KINS]KINEMATICS 3 4# Load motion controller module 5# The "servo_period_nsec" option creates the "servo-thread" thread 6loadrt [EMCMOT]EMCMOT servo_period_nsec=[EMCMOT]SERVO_PERIOD num_joints=[KINS]JOINTS 7 8# Load MESA board controller 9loadrt hostmot2 10 11# Load MESA low-level Ethernet Anything IO boards controller 12# (Mesa Electronics Ethernet Anything IO boards) 13loadrt hm2_eth board_ip="10.68.33.122" config="num_encoders=2 num_pwmgens=0 num_stepgens=1" 14 15# Load ladder language module 16loadrt classicladder_rt 17 18# Load pid module and create a controller for each axis 19loadrt pid names=pid.x,pid.y 20 21# Load estop_latch module to handle emergency stop 22loadrt estop_latch 23 24# Load oneshot module (pulse generator) 25loadrt oneshot 26 27# Load logic module and define a 5-input OR function 28loadrt logic names=logic.fault personality=0x205 29 30# Configure the watchdog timeout for the MESA 7I96S board 31setp hm2_7i96s.0.watchdog.timeout_ns 5000000 32 33# Configure dpll (digital phase locked loop) of the hostmot2 module 34setp hm2_7i96s.0.dpll.01.timer-us -100 35setp hm2_7i96s.0.stepgen.timer-number 1 36setp hm2_7i96s.0.encoder.timer-number 1 37 38# Configure pulse parameters of the oneshot module 39setp oneshot.0.width 0.1 40 41# Add functions to the servo thread 42addf motion-command-handler servo-thread 43addf motion-controller servo-thread 44addf pid.x.do-pid-calcs servo-thread 45addf pid.y.do-pid-calcs servo-thread 46addf hm2_7i96s.0.read servo-thread 47addf hm2_7i96s.0.write servo-thread 48addf classicladder.0.refresh servo-thread 49addf estop-latch.0 servo-thread 50addf oneshot.0 servo-thread 51addf logic.fault servo-thread 52 53# Load classicladder project 54loadusr classicladder myladder.clp --nogui

X-axis configuration (joint 0, stepper motor):

57#******************** 58# AXIS X --- JOINT 0 59#******************** 60 61# --- PID controller parameters --- 62 63setp pid.x.Pgain [JOINT_0]P 64setp pid.x.Igain [JOINT_0]I 65setp pid.x.Dgain [JOINT_0]D 66setp pid.x.bias [JOINT_0]BIAS 67setp pid.x.FF0 [JOINT_0]FF0 68setp pid.x.FF1 [JOINT_0]FF1 69setp pid.x.FF2 [JOINT_0]FF2 70setp pid.x.deadband [JOINT_0]DEADBAND 71setp pid.x.maxoutput [JOINT_0]MAX_OUTPUT 72setp pid.x.error-previous-target true 73setp pid.x.maxerror 1 74 75 76# --- Pulse generator parameters --- 77 78setp hm2_7i96s.0.stepgen.00.control-type 1 # Velocity control 79setp hm2_7i96s.0.stepgen.00.step_type 0 # Step/dir 80setp hm2_7i96s.0.stepgen.00.dirsetup [JOINT_0]DIRSETUP 81setp hm2_7i96s.0.stepgen.00.dirhold [JOINT_0]DIRHOLD 82setp hm2_7i96s.0.stepgen.00.steplen [JOINT_0]STEPLEN 83setp hm2_7i96s.0.stepgen.00.stepspace [JOINT_0]STEPSPACE 84setp hm2_7i96s.0.stepgen.00.position-scale [JOINT_0]STEP_SCALE 85setp hm2_7i96s.0.stepgen.00.maxaccel [JOINT_0]STEPGEN_MAXACCEL 86setp hm2_7i96s.0.stepgen.00.maxvel [JOINT_0]STEPGEN_MAXVEL 87 88 89# --- Encoder parameters --- 90 91setp hm2_7i96s.0.encoder.00.counter-mode 0 92setp hm2_7i96s.0.encoder.00.filter 1 93setp hm2_7i96s.0.encoder.00.scale [JOINT_0]ENCODER_SCALE 94 95 96# --- Connect pid / stepgen / motion signals --- 97 98net pid-x-index-enable => pid.x.index-enable 99 100net pid-x-output <= pid.x.output 101net pid-x-output => hm2_7i96s.0.stepgen.00.velocity-cmd 102 103net pid-x-enable <= joint.0.amp-enable-out 104net pid-x-enable => pid.x.enable 105net pid-x-enable => hm2_7i96s.0.stepgen.00.enable 106 107net pid-x-pos-cmd <= joint.0.motor-pos-cmd 108net pid-x-pos-cmd => pid.x.command 109 110# net pid-x-pos-fb <= hm2_7i96s.0.stepgen.00.position-fb 111net pid-x-pos-fb <= hm2_7i96s.0.encoder.00.position 112net pid-x-pos-fb => pid.x.feedback 113net pid-x-pos-fb => joint.0.motor-pos-fb 114 115 116# --- Configure home / limit signals --- 117 118net x-sw <= hm2_7i96s.0.gpio.000.in 119net x-sw => joint.0.home-sw-in 120net x-sw => joint.0.neg-lim-sw-in

Y-axis configuration (joint 1, brushless motor):

123# MDI Command. Can be specified multiple times. 124# To execute it use the halui.mdi-command-NN pin, 125# where NN is the command number. 126# MDI_COMMAND = G1 X0 Y0 Z0 127 128 129[KINS] 130# Kinematics 131 132# Number of joints (motors). 133JOINTS = 2 134 135# Kinematics module 136# Not used by LinuxCNC directly, used in the HAL file. 137KINEMATICS = trivkins coordinates=XY 138 139 140[APPLICATIONS] 141# Additional applications 142 143# Application to execute. Can be specified multiple times. 144APP=halscope 50000 145 146 147[TRAJ] 148# Trajectory planner configuration 149 150# Controlled axes. Possible values: X, Y, Z, A, B, C, U, V, W. 151# An axis can be specified more than once, e.g., XXYZ. 152COORDINATES = XY 153 154# Units for linear axes. 155LINEAR_UNITS = mm 156 157# Units for rotary axes. 158ANGULAR_UNITS = degree 159 160# Maximum linear velocity, in units per second. 161MAX_LINEAR_VELOCITY = 12.00 162 163# Maximum linear acceleration, in units per second^2. 164MAX_LINEAR_ACCELERATION = 20.0 165 166 167[EMCIO] 168# Input/Output (I/O) controller configuration 169 170# Input/output controller module. 171EMCIO = io 172 173# Period at which EMCIO will be executed. 174CYCLE_TIME = 0.100 175 176 177[AXIS_X] 178# X axis configuration

Other configurations:

182#*************** 183# Other signals 184#*************** 185 186# --- Igus controller alert and error signals --- 187 188net X-alert <= hm2_7i96s.0.7i77.0.0.input-08 189net X-error <= hm2_7i96s.0.7i77.0.0.input-09 190 191net Y-alert <= hm2_7i96s.0.7i77.0.0.input-01 192net Y-error <= hm2_7i96s.0.7i77.0.0.input-02 193 194 195# --- External emergency stop --- 196 197net remote-estop <= hm2_7i96s.0.7i77.0.0.input-13 198 199 200# --- Fault signal (logic.fault) --- 201# The fault signal will be activated if an Igus controller 202# emits an error or alert signal or the user presses the 203# emergency stop button (ESTOP). 204 205net X-alert => logic.fault.in-00 206net X-error => logic.fault.in-01 207 208net Y-alert => logic.fault.in-02 209net Y-error => logic.fault.in-03 210 211net remote-estop => logic.fault.in-04 212 213 214# --- Emergency stop (ESTOP) --- 215 216net user-enable <= iocontrol.0.user-enable-out 217net user-enable => estop-latch.0.ok-in 218 219net user-request-enable <= iocontrol.0.user-request-enable 220net user-request-enable => estop-latch.0.reset 221 222net fault <= logic.fault.or 223net fault => estop-latch.0.fault-in 224 225net emc-enable <= estop-latch.0.ok-out 226net emc-enable => iocontrol.0.emc-enable-in 227 228 229# --- Enable motors --- 230 231net machine-on <= halui.machine.is-on 232net machine-on => hm2_7i96s.0.7i77.0.0.output-00 233 234 235# --- Pulse to start brushless motor rotation program --- 236 237net brushless-ready <= hm2_7i96s.0.7i77.0.0.input-00 238net brushless-ready => oneshot.0.in 239 240net start-brushless <= oneshot.0.out 241net start-brushless => hm2_7i96s.0.7i77.0.0.output-01 242 243 244# --- LED indicators panel --- 245 246net machine-estop <= halui.estop.is-activated 247 248net machine-estop => classicladder.0.in-00 249net remote-estop => classicladder.0.in-01 250net machine-on => classicladder.0.in-02 251 252net X-error => classicladder.0.in-03 253net X-alert => classicladder.0.in-08 254 255net Y-error => classicladder.0.in-05 256net Y-alert => classicladder.0.in-10 257 258net led-red <= classicladder.0.out-00 259net led-red => hm2_7i96s.0.7i77.0.0.output-02 260 261net led-yellow <= classicladder.0.out-01 262net led-yellow => hm2_7i96s.0.7i77.0.0.output-03 263 264net led-green <= classicladder.0.out-02 265net led-green => hm2_7i96s.0.7i77.0.0.output-04

3.8.3. HAL Tools¶

Several HAL tools are available for real-time visualization and diagnosis of pin states. The most notable ones are described below; for a complete list of tools, consult the LinuxCNC user manual [lin23].

3.8.3.1. Halcmd¶

halcmd is a command-line tool for interacting with HAL. When halcmd is executed, the following command line will appear:

halcmd:

This prompt allows you to enter and execute HAL commands. Besides the commands detailed previously in Section 3.8.2, other commands such as show, list, or save can be very useful. These commands enable printing various elements defined in HAL, such as pins, parameters, threads, etc. The complete list of commands is detailed in the halcmd man page, also available at http://linuxcnc.org/docs/html/man/man1/halcmd.1.html.

3.8.3.2. Halshow¶

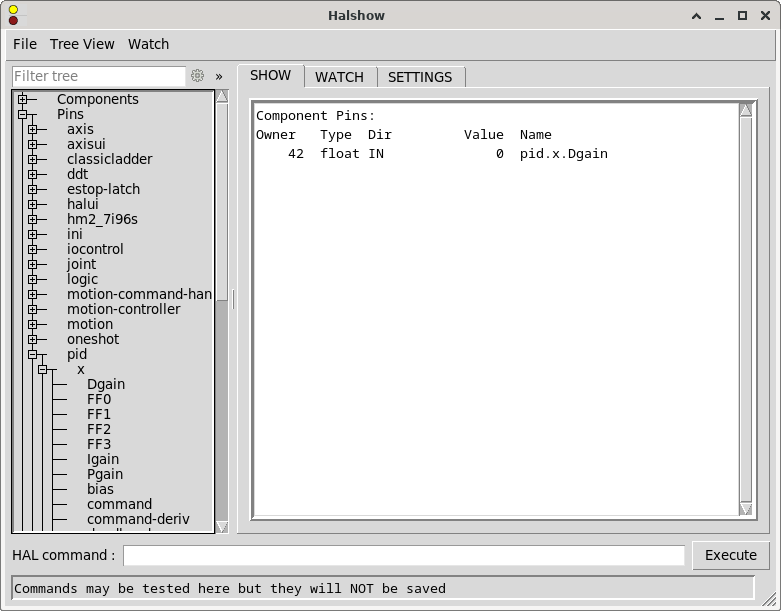

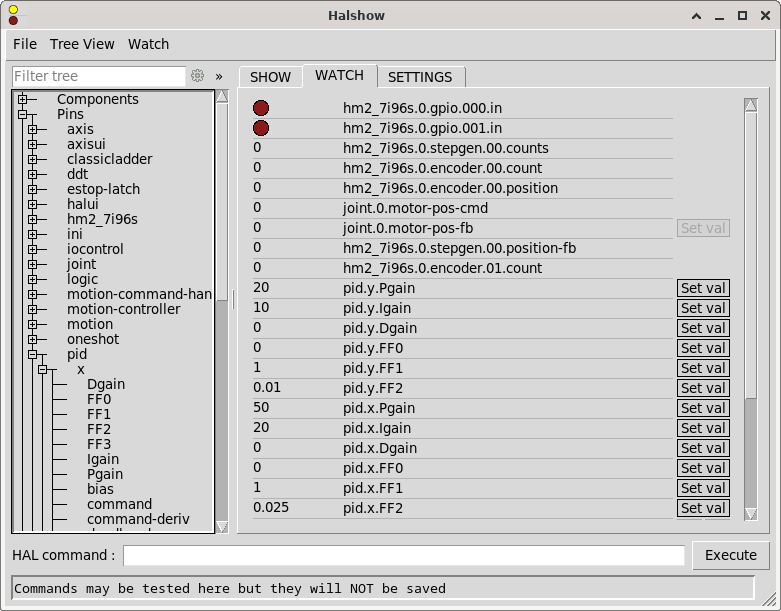

halshow is a graphical tool that allows viewing and monitoring HAL components such as pins, parameters, signals, and functions. This tool is shown in Figures 27 and 28. The tool has the following main elements:

A tree view displaying HAL pins, parameters, signals, functions, etc. This view is located on the left side of the window, as seen in Figures 27 and 28.

A text input field for executing HAL commands, located at the bottom, as shown in Figures 27 and 28.

A “SHOW” tab where information about the selected element in the tree view is displayed, as shown in Fig. 27.

A “WATCH” tab where you can monitor and set values of HAL pins or parameters. Elements can be added here by clicking on them in the tree view, as shown in Fig. 28.

A “SETTINGS” tab with various options such as refresh interval or display format of parameters.

The menu allows saving monitored elements from the “WATCH” tab to a file, as well as loading an existing list of elements to monitor from a file.

You can open the Halshow tool from the AXIS graphical interface by clicking on .

Fig. 27 Halshow tool showing the “SHOW” tab.¶

Fig. 28 Halshow tool showing the “WATCH” tab.¶

3.8.3.3. Halscope¶

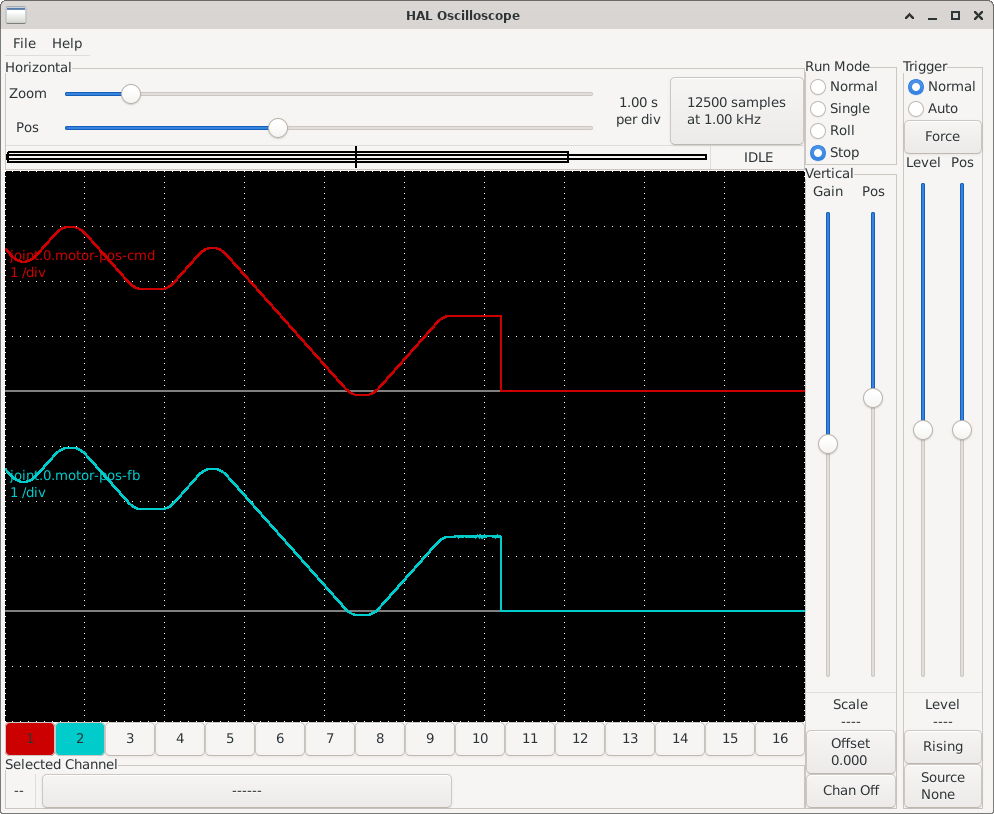

halscope is a graphical tool that provides an oscilloscope for HAL. It allows capturing and displaying the values of pins, signals, and parameters over a period of time. This tool is shown in Fig. 29. The menu allows saving the current configuration or opening a previously saved configuration. When halscope is closed, the configuration is automatically saved to the autosave.halscope file.

Fig. 29 Halscope tool showing the values of joint.0.motor-pos-cmd (motor position commanded by LinuxCNC) and joint.0.motor-pos-fb (motor position read from the encoder) over time.¶

You can open the Halscope tool from the AXIS graphical interface by clicking on .

3.8.3.4. Halreport¶

halreport is a command-line tool that generates a report on HAL connections. The command’s help output is as follows:

Usage:

halreport -h | --help (this help)

or

halreport [outfilename]

The generated report displays all signal connections and indicates potential issues. The information included in the report, among other things, is:

System description and kernel version.

Signals and their connected output, input, and input/output pins.

Functions, threads, and

addfcommands corresponding to each pin.Real names for pins that use aliases.

Signals without an output.

Signals without inputs.

Functions not added to threads.

Warnings about components marked as obsolete.

3.8.4. Ladder Logic Programming¶

LinuxCNC includes the ClassicLadder component, a free implementation of a ladder interpreter published under the LGPL.

Ladder logic, or the ladder programming language, is a method for drawing electrical logic diagrams. Originally conceived to describe control systems using relays, this approach has become a widely used graphical language for programming PLC devices. It derives its name from the fact that programs in this language resemble ladders, with two vertical rails and a series of horizontal rungs between them.

To use ClassicLadder, you must load the classicladder_rt real-time module in HAL and add the classicladder.0.refresh function to the servo-thread thread using the following commands:

loadrt classicladder_rt addf classicladder.0.refresh servo-thread

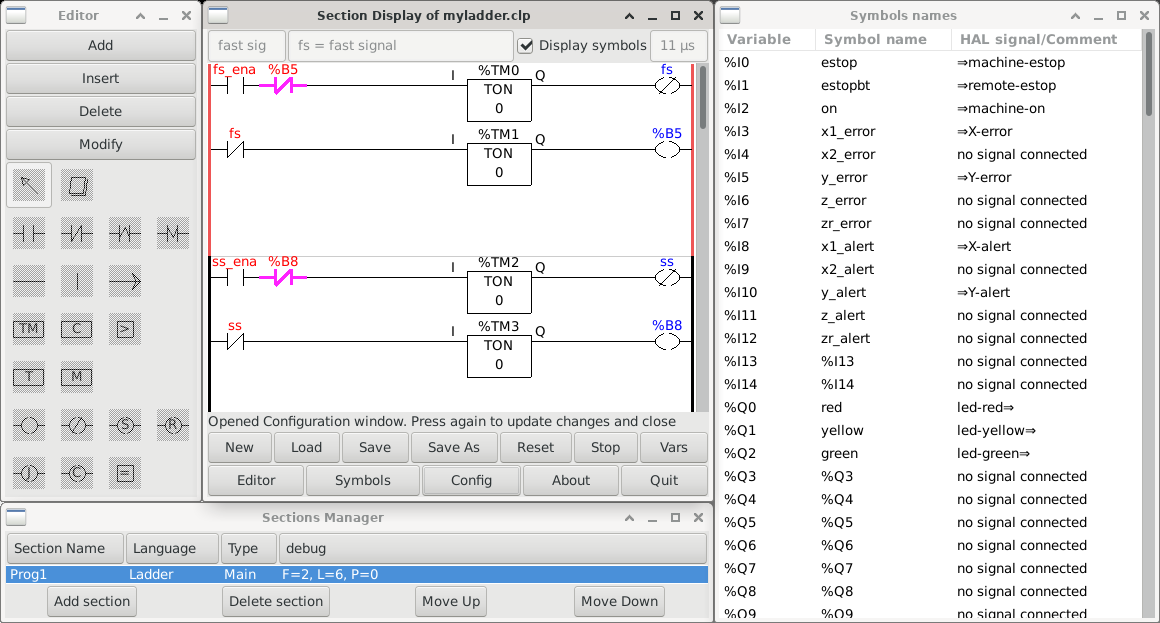

Once this is done, you can open the ClassicLadder graphical interface with the system command classicladder, or from the AXIS interface by clicking on . The ClassicLadder graphical interface allows you to create ladder logic programs, as well as view the logical status of the different program components. This interface is composed of several windows, as shown in Fig. 30.

Fig. 30 ClassicLadder graphical interface.¶

In our testbed setup, ladder logic has been used to program the operation of the LED indicator panel. The program created with ClassicLadder has been saved in the myladder.clp file. To use it in LinuxCNC, it can be loaded with the following HAL command:

loadusr classicladder myladder.clp -nogui

The LinuxCNC user manual [lin23] includes a detailed guide to ClassicLadder. Another good introduction to ClassicLadder is “The Feral Engineer“‘s “Classicladder tutorials” series on YouTube: https://www.youtube.com/playlist?list=PLTYvfbjLClpfAfJSGhZUecgXFwVPY5e09.